Salt Refinery

We are constantly pursuing opportunities to partner with government agencies and institutions to establish a fully operational salt manufacturing plant in their geographic location. Our strong technical know-how clubbed with manufacturing capabilities makes us the preferred partner for salt manufacturing across the globe.

Salt Refinery

Modern technology to refine salt to it purest form.

Product Specification

| NaCl | Above 99% |

| Soluble Matter | 0.4% |

| Insoluble matter other than NaCl | Above 99% |

| Iodine Max. | 40 – 60 ppm |

| Moisture level | Max. 0.3% (At the bottom of the dryer 0.1% - 0.15%) |

| Particle size distribution | All less than 710 microns or as required by buyer |

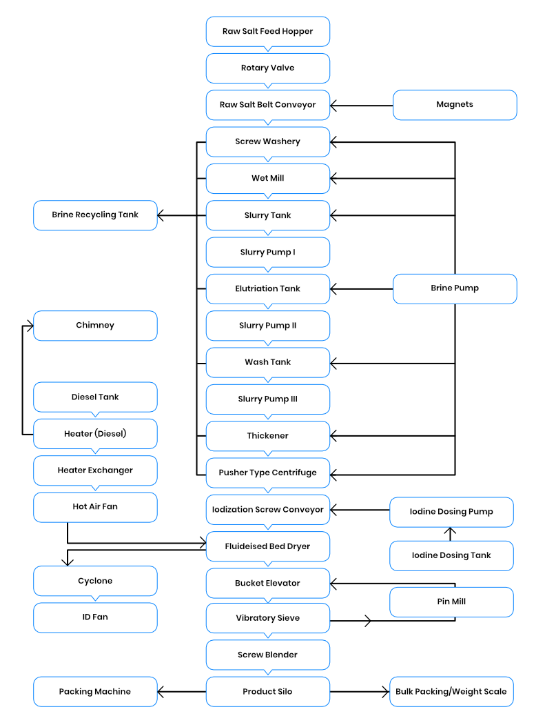

Mechanical Salt Refining Process

Salt Refining Process Description

The Raw Salt will be loaded to the hopper through which it will enter the Special Washing System. The flow rate will be measured here and controlled to set it as per the pre-decided rate based on the purity of raw salt. In the Screw Washery, the major portion of the impurities will be removed. The washed salt will enter the wet Mill Section (Grinding/ Hammer Mill). The brine is added here to give slurry output from the mill. The output is tanked into a slurry tank where further brine is added. The slurry is then pumped to the Elutriation tank for washing. The washed slurry is then transferred to Thickener and decanted brine is transferred to the clarifier by means of Elutriation & wash tank. From here the clear brine is transferred to the brine tank and remaining to the settling pond. Here at settling pond, the settled mud is drained and the upper layer of clear brine is pumped to the Screw Washery. The Salt after removal of water in Thickener is fed to the Centrifuge. In Thickener, the slurry concentration achieved is 50%.

The salt will then be centrifuged to liquid form and it Will be conveyed through the blender cum screw conveyor and belt to fluidized bed dryer. On its way to dryer, it will be iodized.

The washed salt with Iodine Solution will get fluidized in Dryer and Iodine mixing will uniform. Then dry and cooled salt Will come out of FBD and will then travel to Vibro screen through bucket elevator.

After screening, the undersize will be conveyed to a blender cum screw conveyor. Here the Free Flow Agent will be mixed at a specified and predetermined flow rate.

The blender cum conveyor will mix the content well and convey the same to a silo. The finished goods from the silo bottom will be conveyed and distributed by a screw conveyor to Packing Machines. Then the pouches of 1.0 Kg. will be sealed. Another conveyor will carry the refined salt to the bagging and stitching machine where it will be packed in 50Kg bags.